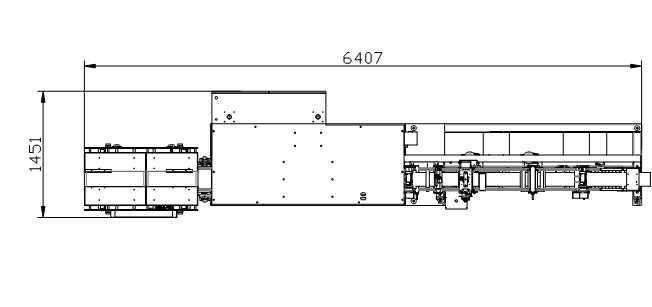

ZB800MC Hand Towel Packaging Machine

Overall dimensions:(Automatic tidy machine+packaging machine)

Main technical parameters:

|

Model |

ZB800MC |

|

|

Film volume |

Maximum diameter |

φ600 mm |

|

Film paper core |

φ76-80mm |

|

|

Packaging film |

Film thickness |

0.06mm—0.09mm; |

|

Film material |

PE Double-sided heat sealing film (recommended), various heat sealing composite film. |

|

|

Speed |

Design speed |

50 packs/min |

|

Packing speed |

30-45 packs/min(Depending on the product characteristics) |

|

|

Power |

Motor power |

11 Kw |

|

Main heating power |

3.0Kw |

|

|

Specifications |

L |

100 mm -250 mm |

|

W |

100 mm -230 mm |

|

|

H |

70mm -90 mm |

|

|

Machine weight |

3000KG |

|

|

Pass rate |

≥97% |

|

|

Overall dimensions |

7000mm×1000mm×2200mm(L×W×H) |

|

|

Power type |

380V (3 Phase 4 line system) |

|

|

Compressed air amount |

6kg/cm2 0.45m3/min |

|

|

Noise |

≤75(db) |

|

|

Note: Due to the different packaging materials and other similar situations, the machine related configuration requirements are different, and the above data may be different from the actual situation. |

||

Technical characteristics:

1.Tidy material conveyorand push material conveyor

- Use frequency conversion motor into the feeding mechanism with the servo motor to stably separate each product;

- When the push mechanism enters, the machinewill not take bags or waste packaging bags;

- The material conveying mechanism has the over-high and over-long automatic detection function

2.Standard machine:

- The main machineadopts 10-axis Mitsubishi JE series servo independent drive, fast response speed, accurate action;

- Control system is equipped with Mitsubishi L series PLC, sports CPU combined with Mitsubishi JE high-resolution servo, high-speed operation performance is more stable;

- Large LCD touch screen display and parameters setting, convenient to change the specifications, the main adjustment parts are marked with the scale, such as the envelope envelope position;

- The bag making and the final seal are controlled by the heating tubeof the Delta temperature control module system, and the stability deviation shall ensure that the bag making of each bag can be completed during the high-speed operation;

- Pneumatic parts adopt Japanese SMC brand, and sports parts adopt Japanese NSK \ THK brand;

- Color mark sensor adopt SICK

3.Transformation and innovation:

- The final sealing part forming mechanism is conveniently adjusted.

- The final sealing part side pressing mechanism is conveniently adjusted.

- The final sealing part outputmechanism is conveniently adjusted.

Packaging effect:

Main electrical configuration:

|

NO. |

Name |

Brand |

Spec |

Qty |

|

1 |

PLC |

Mitsubishi, Japan |

L08H CPU |

1 |

|

2 |

High-speed position module |

Mitsubishi, Japan |

LD77MS16 |

1 |

|

3 |

Servo driver |

Mitsubishi, Japan |

MR-JE-200B |

2 |

|

4 |

Servo driver |

Mitsubishi, Japan |

MR-JE-70B |

3 |

|

5 |

Servo driver |

Mitsubishi, Japan |

MR-JE-40B |

5 |

|

6 |

Servo motor |

Mitsubishi, Japan |

HG-SN152J-S100 |

2 |

|

7 |

Servo motor |

Mitsubishi, Japan |

HG-KN73J-S100 |

3 |

|

8 |

Servo motor |

Mitsubishi, Japan |

HG-KN43J-S100 |

5 |

|

9 |

Servo motor |

Mitsubishi, Japan |

DRP-120-24 |

2 |

|

10 |

Power switch |

Weinview TAIWAN |

XBPE4025C |

2 |

|

11 |

Solid state relay |

Crydom |

KT-50E 12-30V DC |

1 |

|

12 |

Color mark sensor |

BDL |

GS2110-WTBD-N |

1 |

|

13 |

HMI |

Mitsubishi, Japan |

L08H CPU |

1 |