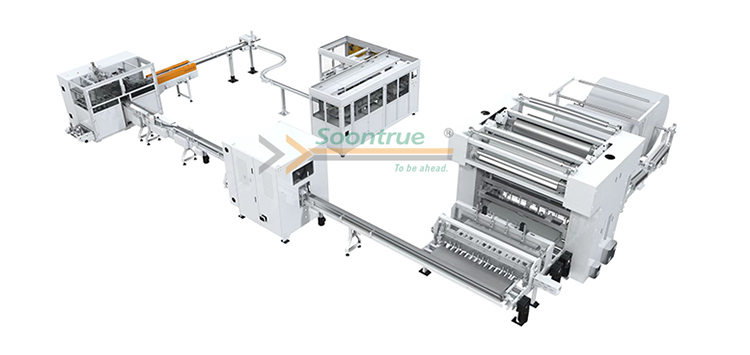

Tissue Paper Folding Machine

Applicable

Soontrue facial tissue making machine with higher performance and easier maintenance at the folding part. converting process, can use wider width parent roll –up to 10 lanes (230mm*10lanes).operation is easy, various functions can be set, and various kinds of small lots are dealt with.

|

Model |

SCZ-175-1500 |

SCZ-200-2000 |

|

Production speed |

100-120 m/min 14 logs/min |

100-120m/min 12 logs/min |

|

Ordinary width |

1430mm(Max)

|

1910mm(Max) |

|

Jumbo roll layers |

2-4 plies

|

2-4 plies

|

|

Jumbo roll |

Double plies, each ply 13.5-18 gsm; 3&4plies: each ply 11-15gsm |

Double plies, each ply 13.5-18gsm; 3&4plies: each ply 11-15gsm |

|

Design log qty |

13 logs/min |

14 logs/min |

|

Open size (mm) |

175mm(+1, -2) (if different ,please specify) |

200mm (+1, -2) (if different ,please specify) |

|

Folded size(mm) |

87.5mm(+1, -1) (if different ,please specify) |

100mm(+2, -0) (if different ,please specify) |

|

Folding part motor power (KW) |

5.5KW |

5.5KW |

|

Vacuum pump power(KW) |

30KW |

37KW |

|

Power type |

380v 50Hz (if different ,please specify)

|

380v 50Hz (if different ,please specify)

|

|

Control voltage (V) |

24 |

24 |

|

Compressed air(MPa) |

≥0.6 |

≥0.6 |

SCZ-175-1500/SCZ-200-2000 facial tissue production line is the latest model independently developed by Soontrue Fengguan Company combined with the world's advanced equipment manufacturing concept. Adopt motion control programming control; Large screen true color man-machine interface operation; Servo + frequency conversion independent drive; Machine photoelectric integration control and other international advanced technology, can automatically detect and adjust every action of the production line, so that the whole production line to achieve the best working condition, is the majority of household paper processing enterprises to produce high-grade pull-out facial tissue paper the best choice.

- SCZ-175-1500/SCZ-200-2000folding machine equipment to achieve external folding tail function. After inter-folding , each group of paper is transferred to the folding mechanism, which can realize half folding of the top (surface) one piece of paper, simple, efficient and practical.

- The folding roller processing mode adopts high-precision deep-hole processing to ensure the rigidity and strength of each roller, so as to ensure the precision requirements of the folding roller in high-speed folding.

- The bottom knife for paper breaking is all processed with imported materials, and the side of the bottom knife is equipped with suction hole structure to ensure that the paper will not turn over when the paper is broken at high speed, so as to make the finished product more tidy.

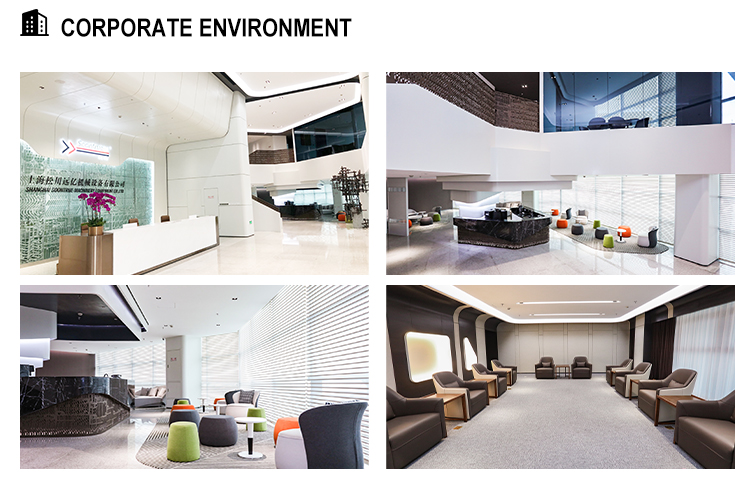

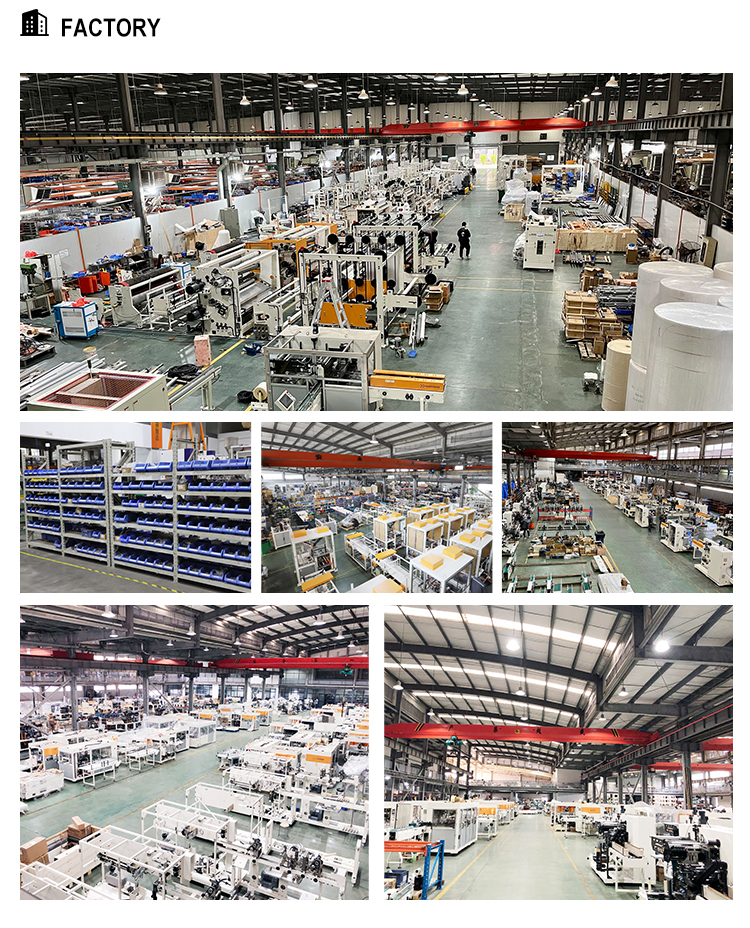

Soontrue is a professional tissue converting and packing machine manufacturer. Founded in 1993, with more than 133,500 square meters plant space and more than 2,000 well-trained and knowledgeable staff members, more than 700 of them are middle and senior technicians ; Our annual revenue reaches over USD300 million; with more than 2,000 patents to make sure our machines leading ahead in the industry.

Soontrue has 4 manufacturing bases which are Shanghai, Foshan, Pinghu, and Chengdu factories, Not satisfied with our achievements in China, over the past few years, we have successfully provided solutions and services for our customers in 160 countries and regions around the world. In China, Soontrue is a famous brand and the machines are widely used in all the big tissue factories, with more than 70% of domestic market share. Innovation,Intelligence, efficiency and service are always what we are striving for, win-win situation with customers is our final goal!

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our tissue manufacturing machine is servo controlled, which greatly simplifies the difficulty of operation and commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. We can also provide instructional videos to give you step-by-step tutorial if necessary.

Q3: If I buy your tissue making machine, what technical support can I get?

Answer: Whether you buy a toilet paper making machine, a paper napkin making machine, or a facial tissue making machine, we will provide you with 24-hour online technical support. In addition, we can also provide you with instructional videos on the installation and daily commissioning and maintenance. For some customized tissue paper production line, our professional after-sales technicians can also provide on-site installation and commissioning services as per request (buyer should bear the cost for the service).

Q4: How do we build trust in the first business?

Answer: We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the best tissue paper making machine you need is ready before shipment.

Q5: How can I find the suitable automatic tissue paper manufacturing machine I need?

Answer: We will fully communicate of the information of your tissue, including the width and diameter of the jumbo roll, pattern type, paper thickness, grammage etc.We have nearly 30 years of experience as a machinery manufacturer and can provide you with similar case videos for your reference.If necessary, we will ask you for samples of your tissue paper and packaging films for testing, in order to find the most suitable and cost-effective solution for you.

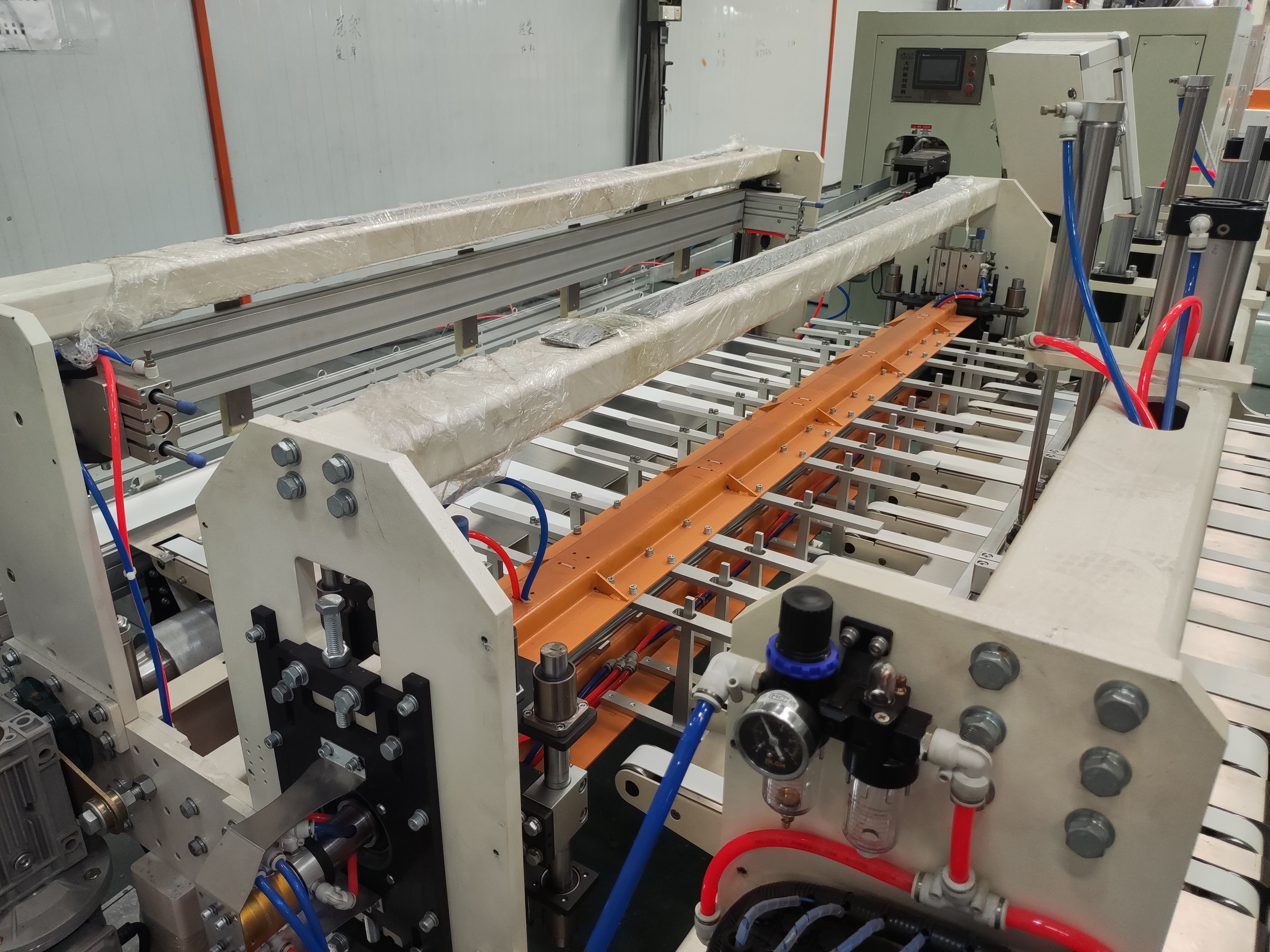

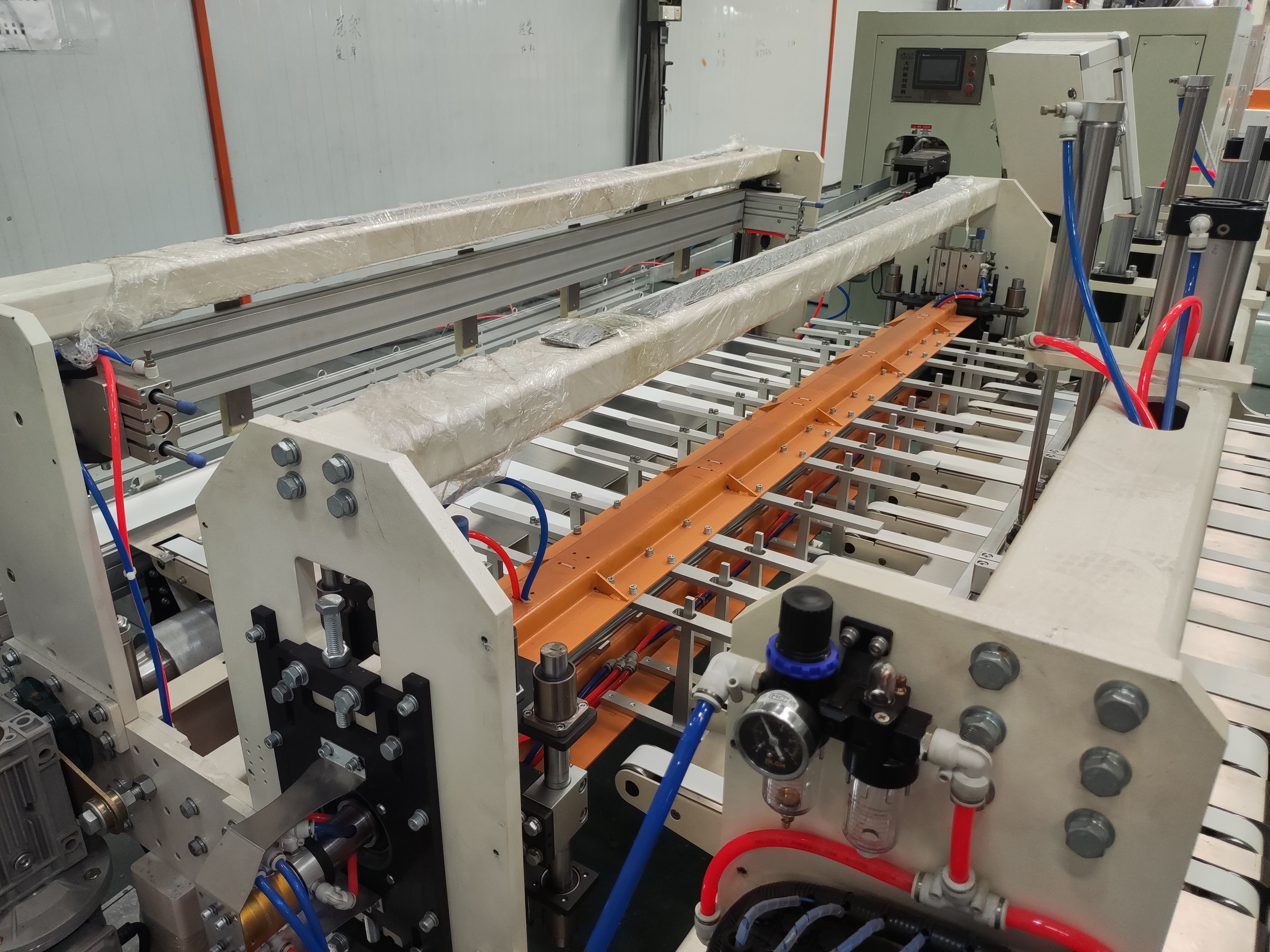

Jumbo roll back stand

Independent motor drive,Roll it clockwise,SCZ-175-1500 Maximum width of jumbo roll (mm) is 1430mm SCZ-200-2000Maximum width of jumbo roll (mm) is 1910mm

With broken paper detection system, the machine stops when the paper is broken, reduce the waste of Jumbo roll

Patten Embossing Unit(Optional)

Integrates with functions of pattern embossing, folding, counting and cutting, realizing high automation and good quality

Embossing pressure mode is Hydraulic& self-lubrication

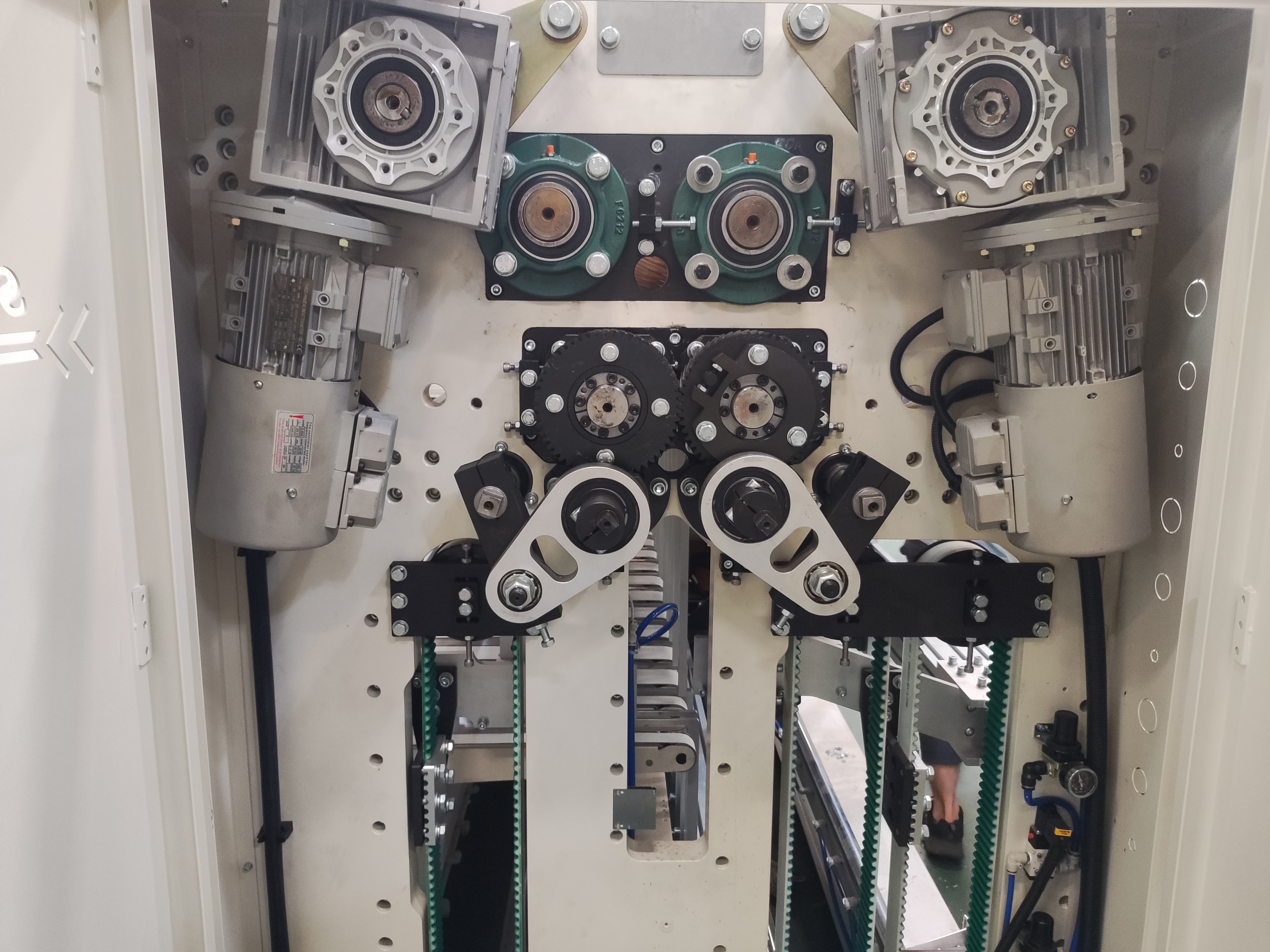

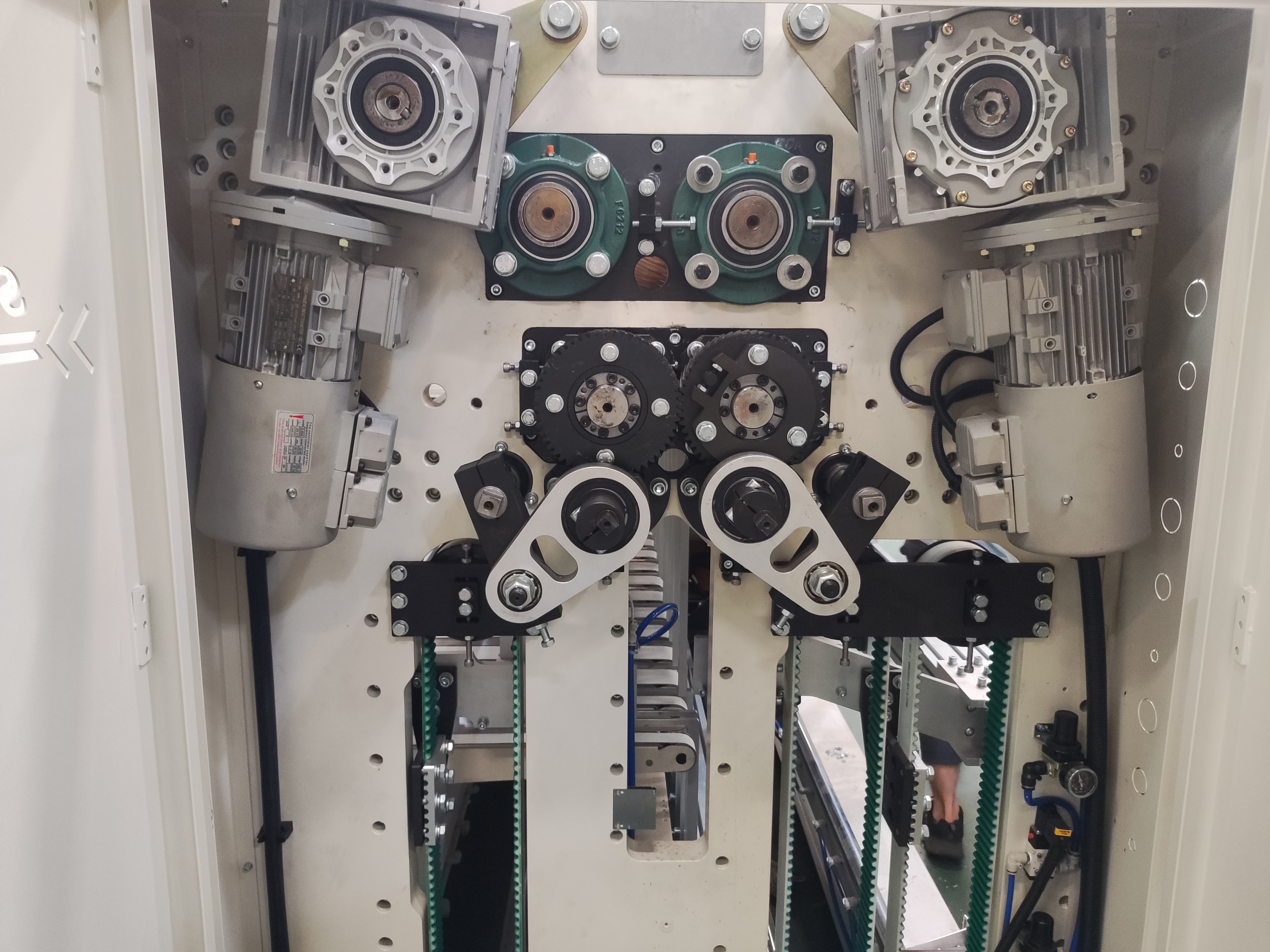

Tissue Paper Folding Part

Wall panel structure (wall panel thickness 50mm)

Using high resolution servo operation, the count is 100% accurate,V - shaped staggered folding

After quenching and tempering treatment, and the use of high-precision deep hole processing, to ensure the steel and strength of each roller, and all are processed by CNC machining center, G3.2 level dynamic balance, to ensure the roller at high speed folding precision

Automatic flip device

This machine can realize the function of folding paper tail outside the machine. After folding, each group of paper is transferred to the folding mechanism, which can realize half folding of the top (surface) piece of paper, which is simple, efficient and practical.

Log saw(Rotary tissue cutter)

Delta PLC and touch screen control system which guarantee the stability of the machine.

Single Packaging Machine