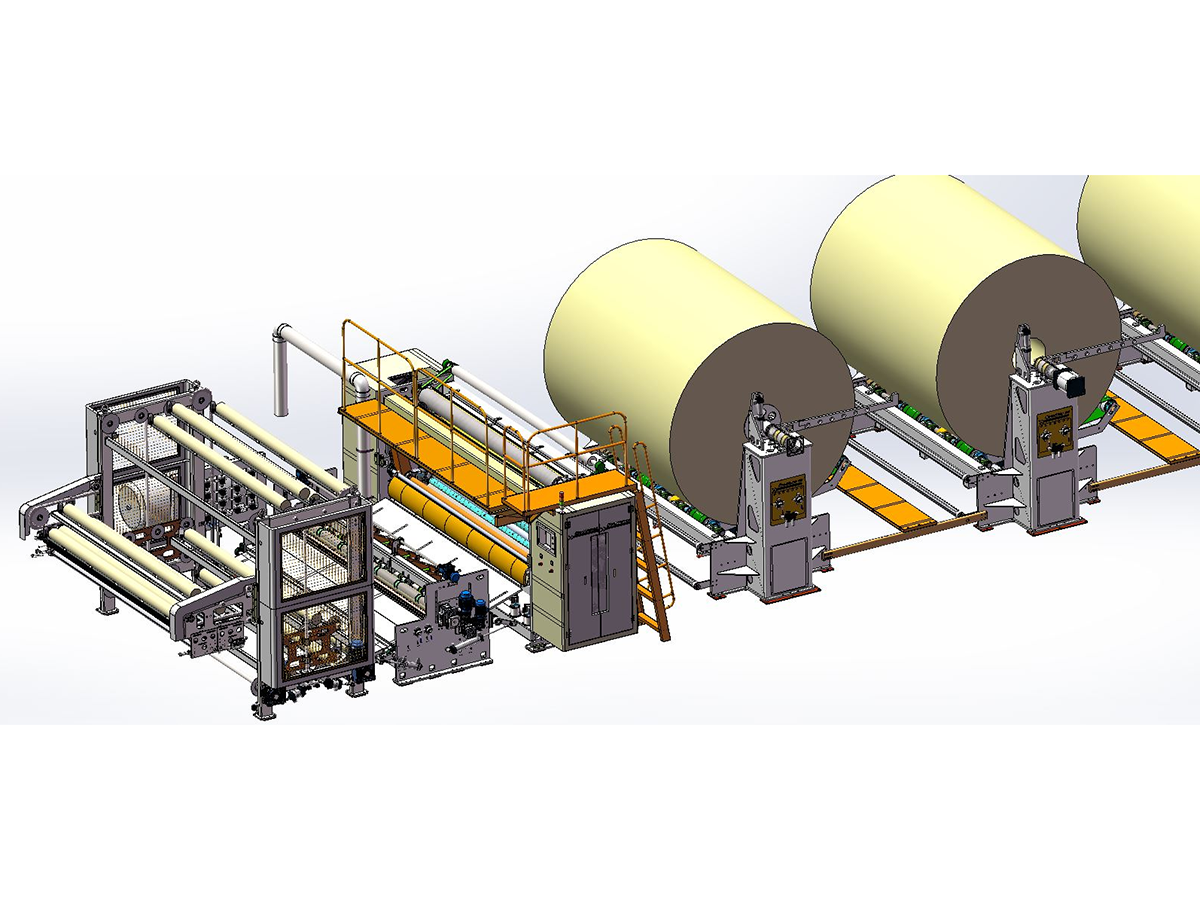

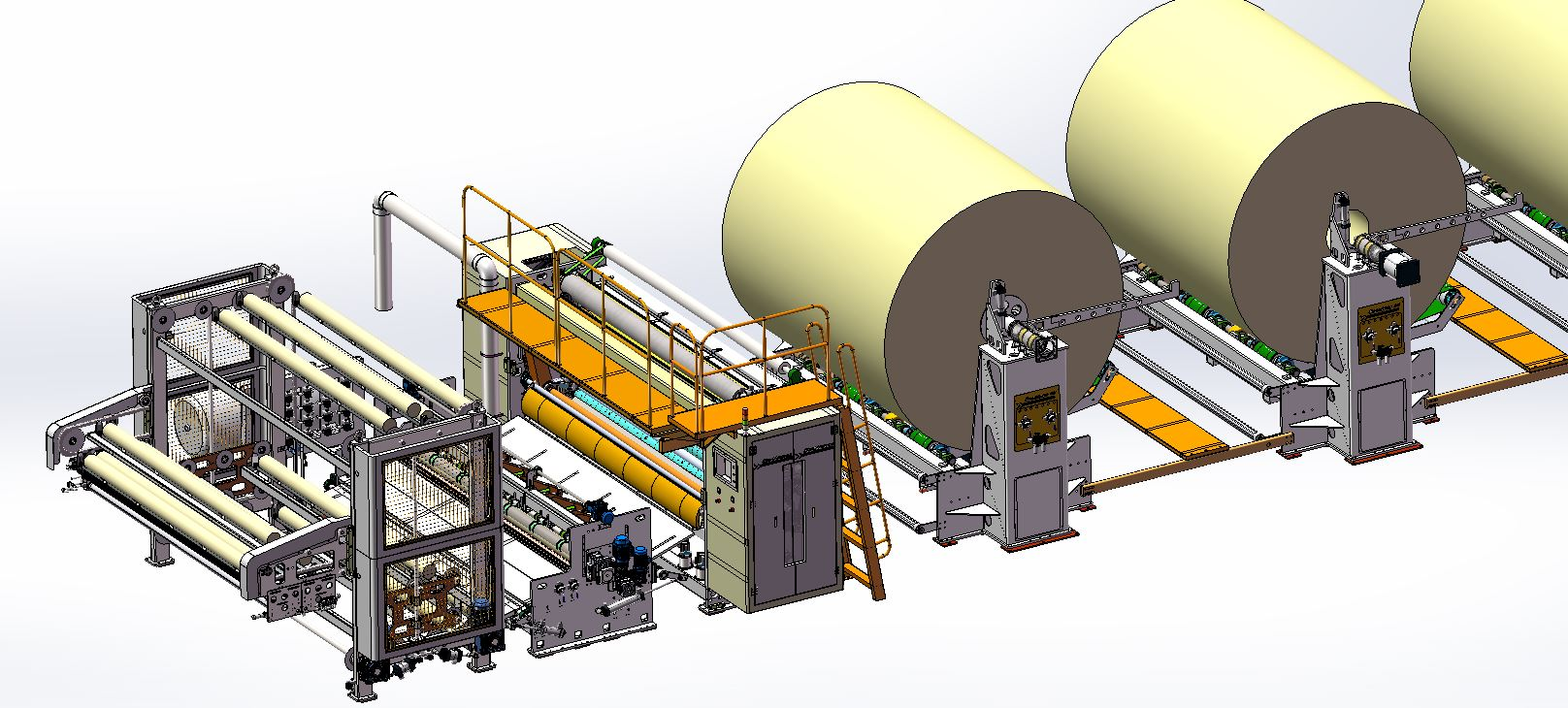

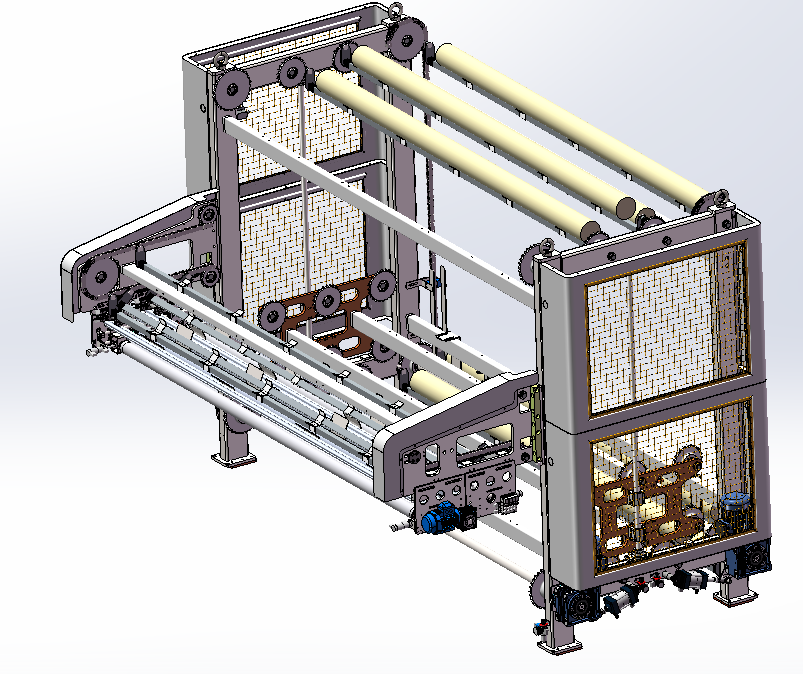

SCF-350C-2900 High Speed Rewinding Machine

SCF-350C-2900 High Speed Rewinding Production Line is the latest model independently developed by Soonture Group in combination with the world's advanced equipment manufacturing concept. It adopts imported motion controller control, large screen true color human-machine interface operation, servo + variable frequency independent drive, mechanical and optical integrated control and other international advanced technologies, which can automatically detect and adjust each action of the production line to make the whole production line reach the best working condition. It is the best choice to produce high-grade toilet roll and kitchen roll.

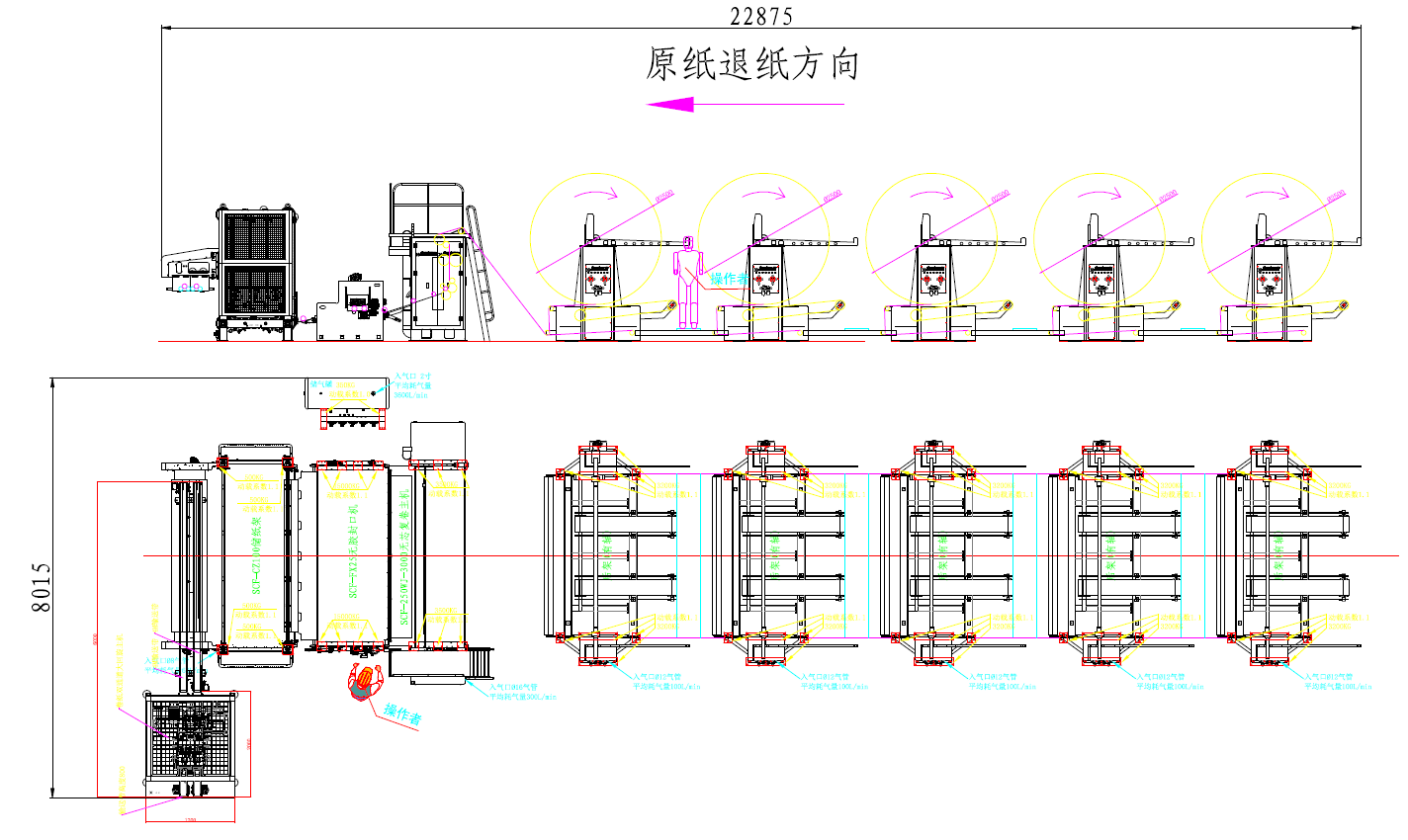

Machine layout

Design speed:

with core rewinding: 350 m/min

Production speed:

with core rewinding: 300 m/min

Ordinary width: 2900 mm

Suitable for raw material: straw pulp paper, wood pulp paper, sugarcane pulp paper, bamboo pulp paper, etc.

This rewinding production line integrates core-rewinding and coreless rewinding functions, has applied for a number of invention patents, and is in a leading position worldwide. High-speed rewinding production has greatly improved production efficiency and reduced production costs, bringing core-rewinding and coreless rewinding technologies into a new era.

Machine configuration:

|

No. |

Item |

Qty |

Unit |

Remark |

|

1 |

SCF-350C Back stand |

1 |

Group |

With shaft |

|

2 |

SCF-350C Machine machine |

1 |

Set |

Including edge pressing part |

|

3 |

SCF-350C Sealing machine |

1 |

Set |

|

|

4 |

SCF-350C Paper accumulator |

1 |

Set |

|

|

5 |

SCF-350C Fully automatic high speed rewinding machine |

1 |

Set |

|

|

6 |

SCF-350C Core Automatic Conveying Device |

1 |

Set |

|

|

7 |

SCF-350C Tube core machine |

1 |

Set |

Optional |

|

8 |

SCF-350CSS 1 embosser |

1 |

Set |

Optional |

|

9 |

SCF-350C 2 embossers |

1 |

Set |

Optional |

|

10 |

SCF-350C Glue lamination |

1 |

Set |

Optional |

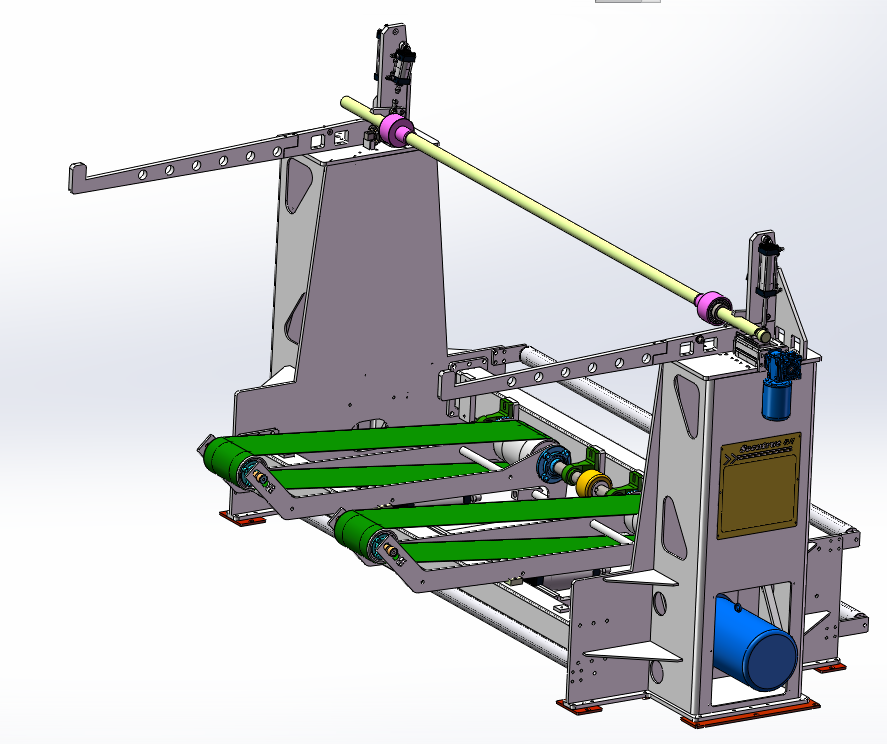

1.SCF-350Cback stand 1 group/line

|

No. |

Item |

Technical parameter |

|

1 |

Width of jumbo roll |

2850mm (Max) |

|

2 |

Diameter of jumbo roll |

¢2000mm (Max) |

|

3 |

Weight of jumbo roll |

2.5t (Max) |

|

4 |

Unwinding system |

Pneumatically controlled sending paper belt unwinding |

|

5 |

Unwind seat |

Soontrue paper shaft with paper core tube diameter 76, if there is any special, please mention |

|

6 |

Jumbo roll centralizing |

Control-ed by touch screen |

|

7 |

Tension control |

With floating roller auto tension adjusting device |

|

8 |

Roll unwind type |

First roll clockwise |

|

9 |

Jumbo roll web type |

Manual |

|

10 |

Guiding roller turning type |

with slave drive type |

|

11 |

Paper break detection |

With paper break detection system (between the floating roller and the paper feed roller |

|

12 |

Power |

Main motor 15KW/ group, jumbo roll centralizing adjustment motor 0.37KW/ group

|

|

13 |

Lowest air pressure |

0.6Mpa |

|

14 |

Air consumption |

about 1m³/group/hour |

|

15 |

Machine weight |

3000KG/group |

|

16 |

Dynamic load coefficient |

1.1 |

|

17 |

Drive |

Independent motor drive, timing belt, flat belt |

|

18 |

Guard |

Protect for main drive part |

2.SCF-350CMain machine 1set/line

|

No. |

Item |

Technical parameter |

|

1 |

Jumbo roll maxi width |

2850mm |

|

2 |

Design speed |

300m/min |

|

3 |

With core stable speed |

250m/min (according to different spec the speed will differ) |

|

6 |

Rewinding type |

Continuous operation, jumbo roll loading, jumbo roll changing, no need to stop the machine |

|

7 |

Paper break type |

Rear scraper for paper breaking; |

|

8 |

Machine structure |

Wallboard type |

|

9 |

Finished roll diameter |

With core: ¢90~¢130mm |

|

10 |

Rewinding diameter adjustment |

HMI Control (servo control) the diameter precisely, the control precision is +/-2mm |

|

11 |

Re-winder length |

HMI control (servo control) the pitches length precisely, the control precision is +/-1 pcs; |

|

12 |

Jumbo roll tension control |

The position of floating roller is controlled by HMI, and the jumbo roll tension is controlled by electric power conversion. |

|

13 |

Finished rolls core tube out-diameter |

¢35~¢50mm (According to customer’s requirements ) |

|

14 |

Machine jogging function |

Have |

|

15 |

Paper core automatic input |

AC motor intermittent exercise drives the push chain to transfer the paper core, and the servo motor controls the paper core to the rewinding area |

|

16 |

Paper core tube gluing method |

Using glue plate built-in roof with spring plate pressing mode intermittent gluing |

|

17 |

Edge embossing function |

Equipped with a complete set of edge embossed devices, totally 30 sets of embossing unit |

|

18 |

Edge embossing method |

The edge pressing device is installed in the head of the rewinding machine, and the whole air bag is used to realize the embossing. The air bag with good material has even pressure. |

|

19 |

Edge embossing wheel |

The bearing surface is treated with electric engraving pattern; With manual lubrication device; |

|

20 |

Edge embossing spec |

Embossing pattern shall be provided by the buyer (Buyer prepare) |

|

20 |

Punching device

|

1. A spiral punching roller with four pieces of punching up cutter on it

2. A fixed punching roller, one pcs of punching tooth cutter

3. The loading and unloading of punching knife is realized by cylinder; During jog function, you can choose to load or unload the punch knife, when the machine runs normally, the punch knife automatically loaded

4. Paper breaking automatic induction knife shaft protection system, when there is jammed paper, broken paper, the punching knife will be automatically off

5. The punching knife is lubricated by oil felt and manually oil filling

6. Easy tear pitch size is adjusted by the servo motor which controls the punching roller; Pitch size accuracy is +/-1mm

7. Pitch punching angle adjustment: manual adjustment |

|

21 |

Proportion of virtual tangent cut |

3mm:1mm |

|

22 |

Jumbo roll web method |

Manual |

|

23 |

New roll rewinding after alarm stopping

|

Press the reset button to start a new cycle, and the count will be cleared automatically to reduce further waste.

|

|

24 |

S-shaped in-feeding paper device |

Before pitch punching, with S shape pulling roller, the tension of punching and rewinding area can be adjusted by through conical wheel belt |

|

25 |

Broken paper detection |

With three broken paper reflective photoelectric detection system (between the punching unit and the paper rollers) |

|

26 |

Power |

Main motor 18.5KW, riding roller servo motor 7KW, lower rewinding roller servo motor 5KW, paper core loading servo motor 5KW, cone wheel regulation motor 0.12kW, the total power 51.1KW, the coreless function needs to add 30KW vacuum pump, the total power of 82.1KW |

|

27 |

Minimum pressure requirement |

0.6Mpa |

|

28 |

Air consumption |

Around 7m³/h |

|

29 |

Machine weight |

About 12000KG |

|

30 |

Dynamic load coefficient |

1.23 |

|

31 |

Drive |

Independent motor drive, servo motor, synchronous belt, flat belt drive |

|

32 |

Embossing roller |

Synchronous belt drive, flat belt drive |

|

33 |

Ride roller control |

Synchronous belt, servo motor |

|

34 |

Lower rewinding roll control |

Servo motor |

|

35 |

Paper core input |

Servo motor |

|

36 |

Guard |

All the main drive parts should be protected with protective cover |

3.SCF-350CSealing device 1set/line

|

No. |

Item |

Technical parameter |

|

1 |

Jumbo roll maxi width(mm) |

2850 |

|

2 |

Design speed |

20 Strips/min |

|

3 |

Production speed |

15 Strips/min |

|

4 |

Finished roll diameter range |

¢70~¢130mm |

|

5 |

Sealing way

|

Reciprocating nozzle spraying glue for sealing

|

|

6 |

Paper tail length |

10-30mm Adjustable |

|

7 |

Paper tail length tolerance |

±3mm |

|

8 |

The glue system |

Spray nozzle, change the size of spray nozzle, can realize the adjustment of spray quantity |

|

9 |

Glue spraying way

|

Use glue pot (more than 20 kg capacity) sealed pressure, PLC control solenoid valve to control the start and end time of spraying glue; this can avoid glue waste |

|

10 |

Finished roll diameter changing |

Manual adjustment, convenient and reliable adjustment |

|

11 |

Paper tail roller |

After sealing, turn the pressure roller and press the paper tail to make the sealing firm and beautiful |

|

12 |

Power |

Sealing motor 1.5KW, paper roll turning motor 0.75KW, paper backing motor 2.2KW, paper pressing motor 0.25KW, total power 4.7KW |

|

13 |

Minimum pressure requirement |

0.6Mpa |

|

14 |

Air consumption |

About 6m³/h |

|

15 |

Machine weight |

2000KG |

|

16 |

Dynamic load coefficient |

1.1 |

|

17 |

Drive |

Independent motor drive |

|

18 |

The glue system |

Linear guide rail guiding, flat belt drive |

|

19 |

Paper roll rotation |

Flat belt drive, synchronous belt drive |

|

20 |

Roll out |

Rod link mechanism |

|

21 |

Guard |

Protect all the drive components with guarding cover |

4.SCF-350CAccumulator 1set/line

|

No. |

Item |

Technical parameter |

|

1 |

Jumbo roll max width |

2850mm |

|

2 |

Fastest unloading |

20 Strips/min |

|

3 |

Finished roll diameter range |

Diameter range from 70 to 130mm |

|

4 |

Operation mode |

Paper roll first in first out working mode, reliable operation, no unreasonably rolls falling |

|

5 |

Storage qty |

Maximum effective storage of 80 paper rolls (128 rolls in total) |

|

6 |

Storage method |

Rectangular tube and plastic bracket and plastic lifting arm; |

|

7 |

Unloading way |

Choose any channel or double channel or three channel unloading through the touch screen, can be separated from the production line to run alone |

|

8 |

Lubricating system

|

Oil cup filling |

|

9 |

Overload protection |

It has overload protection function |

|

10 |

Power |

2.2KW |

|

11 |

Minimum pressure requirement |

0.6Mpa |

|

12 |

Machine weight |

4000KG |

|

13 |

Dynamic load coefficient |

1.05 |

|

14 |

Air consumption

|

About 1m³ / h |

|

15 |

Drive |

Independent motor drive, chain drive |

|

16 |

Guard |

All the main drive components are protected with a guard cover |

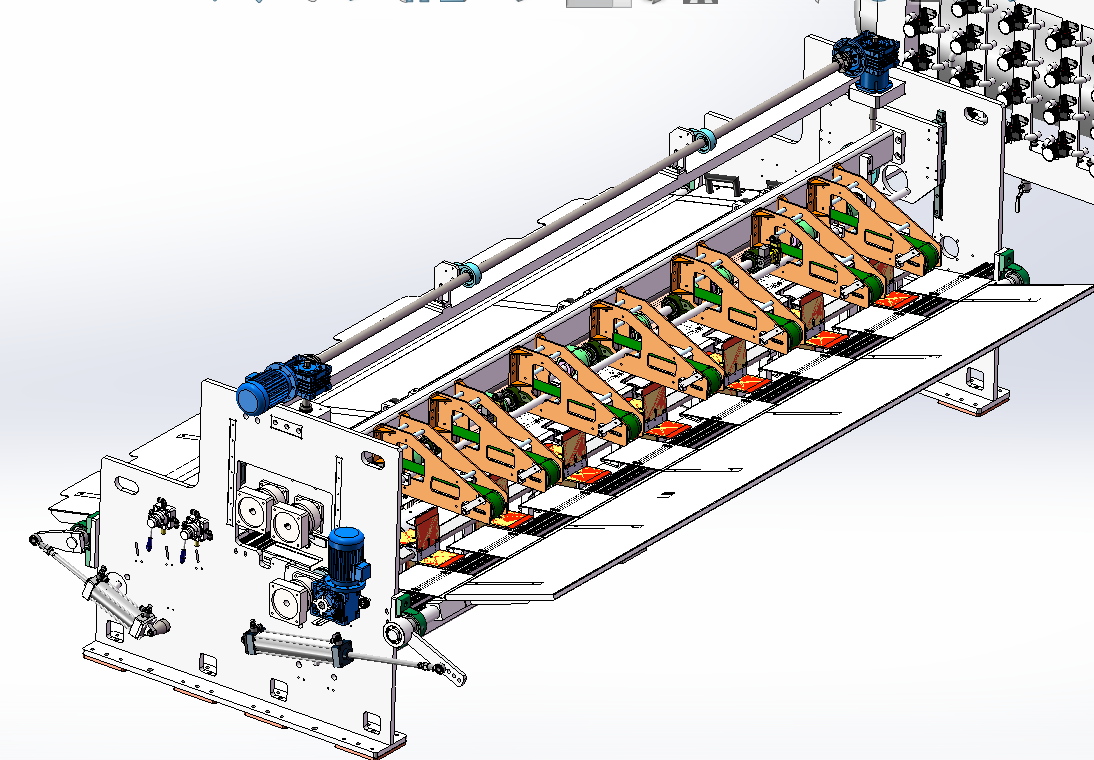

5.SCF-350C Tube core automatic conveying device 1set/line

|

No. |

Item |

Technical parameter |

|

1 |

Jumbo roll maximum width |

2850mm |

|

2 |

Design speed |

30 strips/min |

|

3 |

Basic components |

Paper core automatic lifting device, tubes storage device, tubes mixing device, tubes distributor, drive belt |

|

4 |

Tube core delivery |

It is similar to the chain board machine to lift the tubes into the tube storage shelf, which can hold 600 tubes. The distributor at the bottom separates the single paper tube to the conveyor belt according to the machine instructions, and the conveyor belt transfers the paper tube to the paper tube feeding mechanism of the rewinding machine. |

|

5 |

Tube loading method |

Controlled by the chain with the support plate mode |

|

6 |

Machine structure |

Frame, conveying beam |

|

7 |

Paper tube detection |

With two sets of tube core detection system: detecting whether there are enough tubes at the machine head; rewinding area has tubes or not ; With alarms display until machine stops |

|

8 |

Power |

Tube core loading motor 0.55KW, tube core mixing motor 0.55KW, tube core conveying motor 0.75KW, total power 1.85KW |

|

9 |

Minimum pressure requirement |

0.6Mpa |

|

10 |

Air consumption |

About 1m³ / h |

|

11 |

Machine weight |

2500KG |

|

12 |

Drive

|

Three independent motor drive, respectively drive the elevator 0.55KW, the mixing device 0.55KW, drive belt 0.75KW, using flat belt, chain drive |

|

13 |

Guard |

All the main drive components are protected with guarding cover |

6.SCF-350C Single embosser(Optional)1set/line

|

No. |

Item |

Technical parameter |

|

1 |

Jumbo roll maximum width(mm) |

2850mm( Take 2900 model as example) |

|

2 |

Design speed(m/min) |

300m/min |

|

3 |

Production speed(m/min) |

250m/min |

|

4 |

Embossed steel roller |

According to the customer's pattern, we can use electric carving or corrosion technology, and the pattern is confirmed by both parties |

|

5 |

Embossing rubber roller |

Adopt 45# mandrel, surface cast rubber treatment |

|

6 |

Embossing system |

The embossing roller is fixed by a slider, which is convenient for replacing the embossing roller |

|

7 |

Tension control |

Automatic tension adjustment device with floating roller |

|

8 |

Pressure regulation |

Cylinder loading pressure, limit screw to adjust the pressure |

|

9 |

Paper break detection |

With paper break detection system |

|

10 |

Paper dispersing device |

Using cast rubber curved rollers and curved steel tubes to spread paper |

|

11 |

Power |

Embossing motor 22KW, total power 22KW |

|

12 |

Minimum air pressure requirement |

0.6Mpa |

|

13 |

Air consumption |

About 2m³/h |

|

14 |

Machine weight |

5900KG |

|

15 |

Transmission |

Independent motor drive |

|

16 |

Embossing transmission |

Synchronous belt drive |

|

17 |

Protection |

Main transmission parts are protected by protective covers |

|

18 |

Finger protection |

Install anti-pinch device between embossing rollers |

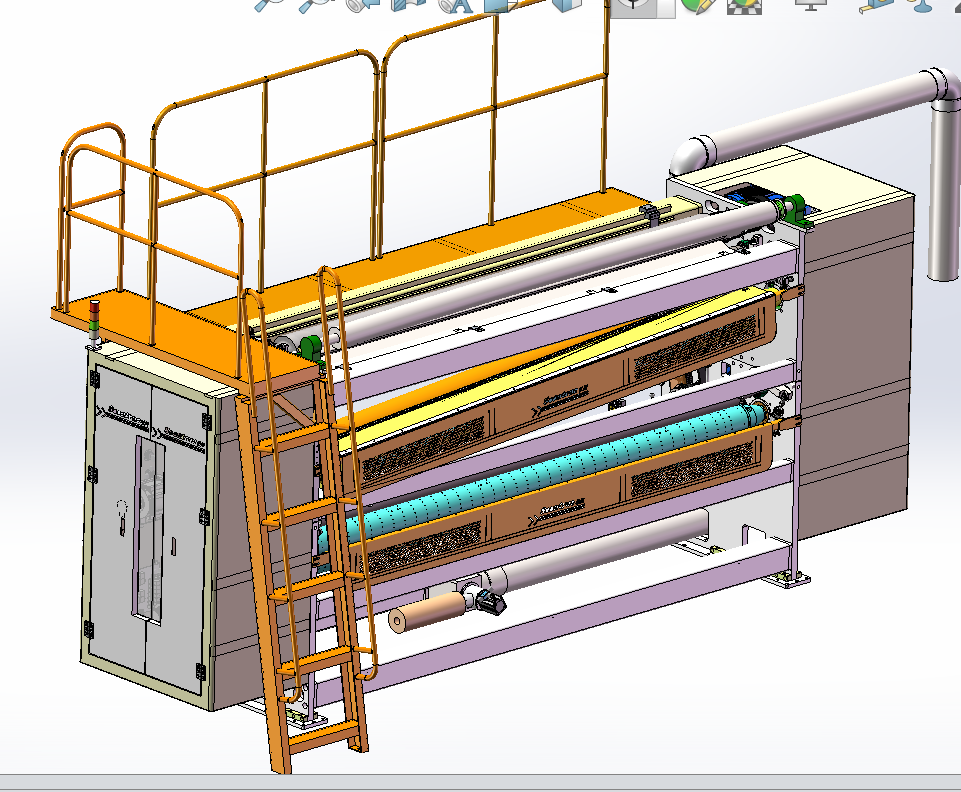

7.SCF-350C Double embosser(Optional) 1set/line

|

No. |

Item |

Technical parameter |

|

1 |

Jumbo roll maximum width(mm) |

2850mm(Take 2900 model as an example) |

|

2 |

Design speed |

300m/min |

|

3 |

Production speed |

250m/min |

|

4 |

Embossing steel roller (2 pcs) |

Roller diameter Φ395 |

|

5 |

Embossing rubber roller (2pcs) |

Roller diameter Φ382 |

|

6 |

Embosser system |

The embossing roller is fixed by a slider, which is convenient for replacing the embossing roller |

|

7 |

Tension control |

Automatic tension adjustment device with floating roller |

|

8 |

Embossing depth adjustment |

Cylinder loading pressure, limit screw adjusts embossing depth |

|

9 |

Paper break detection |

With paper break detection system |

|

10 |

Paper dispersing device |

Using cast rubber curved roller to spread paper |

|

11 |

Power |

30KW |

|

12 |

Minimum air pressure requirement |

0.6Mpa |

|

13 |

Air consumption |

About 2m³/h |

|

14 |

Machine weight |

About 10000KG |

|

15 |

Transmission |

Independent motor drive , synchronous belt , flat belt drive |

|

16 |

Protection |

Main transmission parts are protected by protective covers |

|

17 |

Finger protection |

Install an anti-pinch device between the two rollers |

8.SCF-350C Glue lamination(Optional) 1set/line

|

No. |

Item |

Technical parameter |

|

1 |

Maximum width of base paper (mm) |

2850mm (for Model 2900)

|

|

2 |

Design speed |

300 m/min

|

|

3 |

Production speed |

250 m/min

|

|

4 |

2 Embossing roller steel |

Roller face diameter: 395 |

|

5 |

2 Embossing roller |

Roller face diameter: 382 |

|

6 |

1 composite rubber roller |

Roller face diameter:359 |

|

7 |

1 rubber roller |

Roll surface diameter φ 325(please confirm the width of jumbo roll width with the customer) |

|

8 |

1 Anilox roller |

Roller face diameter: 265 |

|

9 |

Closed cavity scraper system

|

Adopt the closed cavity scraper system to transfer the glue evenly to the rubber roller |

|

10 |

Pump system |

Plastic water tank (including pneumatic pump)1 set |

|

11 |

Tension control |

Automatic tension adjusting device with floating roller |

|

12 |

Embossing depth adjustment |

Cylinder loading pressure, limit screw to adjust the depth of embossing |

|

13 |

Broken paper detection |

With |

|

14 |

Scattered paper device |

Using cast rubber arc roller and arc steel pipe loose paper |

|

15 |

Jumbo roll web method

|

Manual |

|

16 |

Power |

Main motor is 45KW, mesh roller motor is 4KW, and the total power is about 50KW |

|

17 |

Minimum pressure requirement |

0.6Mpa |

|

18 |

Air consumption |

About 6m³ / h |

|

19 |

Machine weight |

About 13,000kg |

|

20 |

Drive |

Independent motor drive, synchronous belt, gear drive |

|

21 |

Guard |

The main drive parts are protected with protective covers |

|

22 |

Hand protection |

Install anti-hand clamp device between embossing roller |