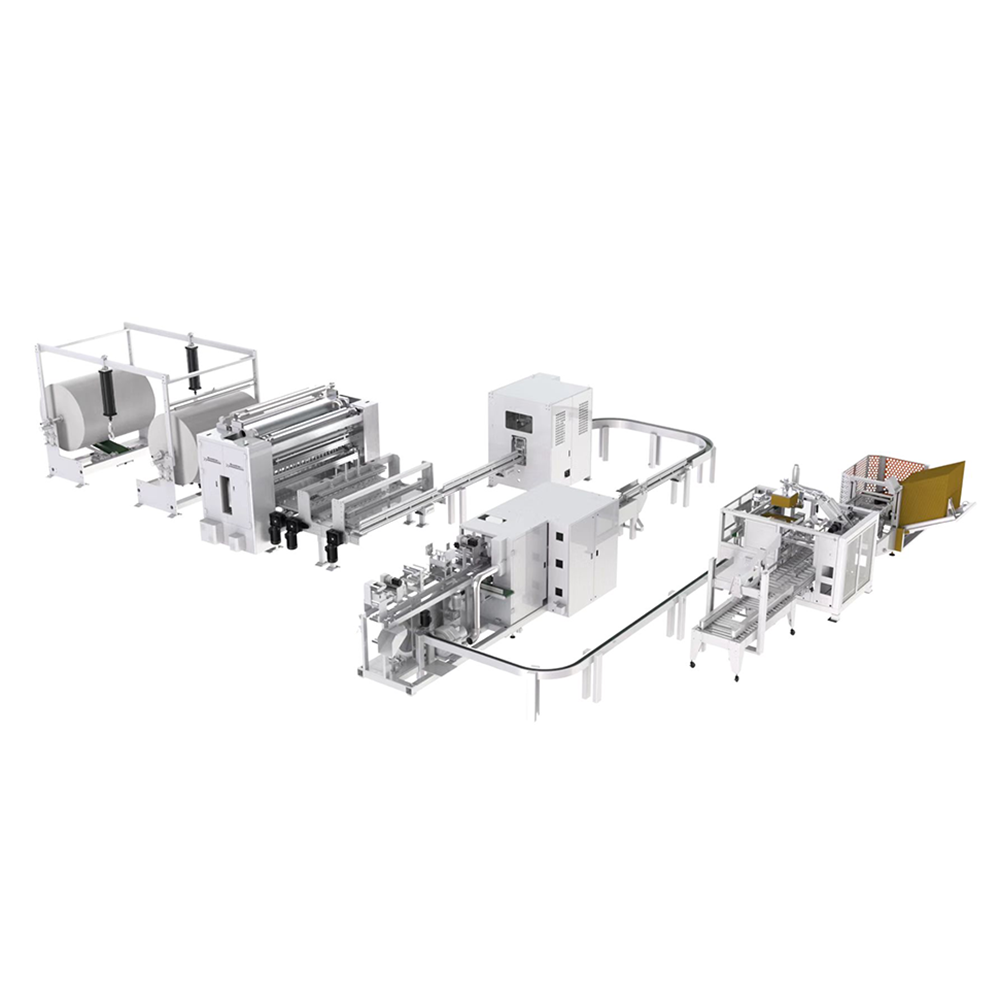

SCZM-200-1650 Cotton Towel Full Automatic V Folding Machine

Main technical parameters:

Design speed:100m/min,

Stable speed:80m/min or 8-10logs/min

Max jumbo roll width:1650mm

Specifications:200mm(Other sizes can be customized)

Raw material:Full cotton, full adhesive or sticky polyester and other non-woven cloth

Single ply ,gram weight 40-100g / ㎡

|

Optimum effective raw material width (Unit:mm) |

1632-1650 |

1600-1610 |

|

1560-1578 |

1518-1546 |

|

|

1485-1505 |

1453-1465 |

|

|

1413-1423 |

1371-1381 |

|

|

*In order to avoid reducing the waste of raw materials and achieve the best effect of the machine, it is recommended to use the above width of raw materials for production! |

||

SCZM-200-1650 Configuration:

Includes the following sections:

|

No. |

Name |

Qty |

Unit |

Remarks |

|

1 |

SCZM-200-1650 Back stands |

2 |

SET |

|

|

2 |

SCZP-1650 Deviation correcting device |

1 |

SET |

ROptional |

|

3 |

SCZM-200-1650Folding part |

1 |

SET |

|

|

4 |

SCZM-200-1650Automatic stacking |

1 |

SET |

|

|

5 |

SCZM-1650 Logs accumulator |

1 |

SET |

£Optional |

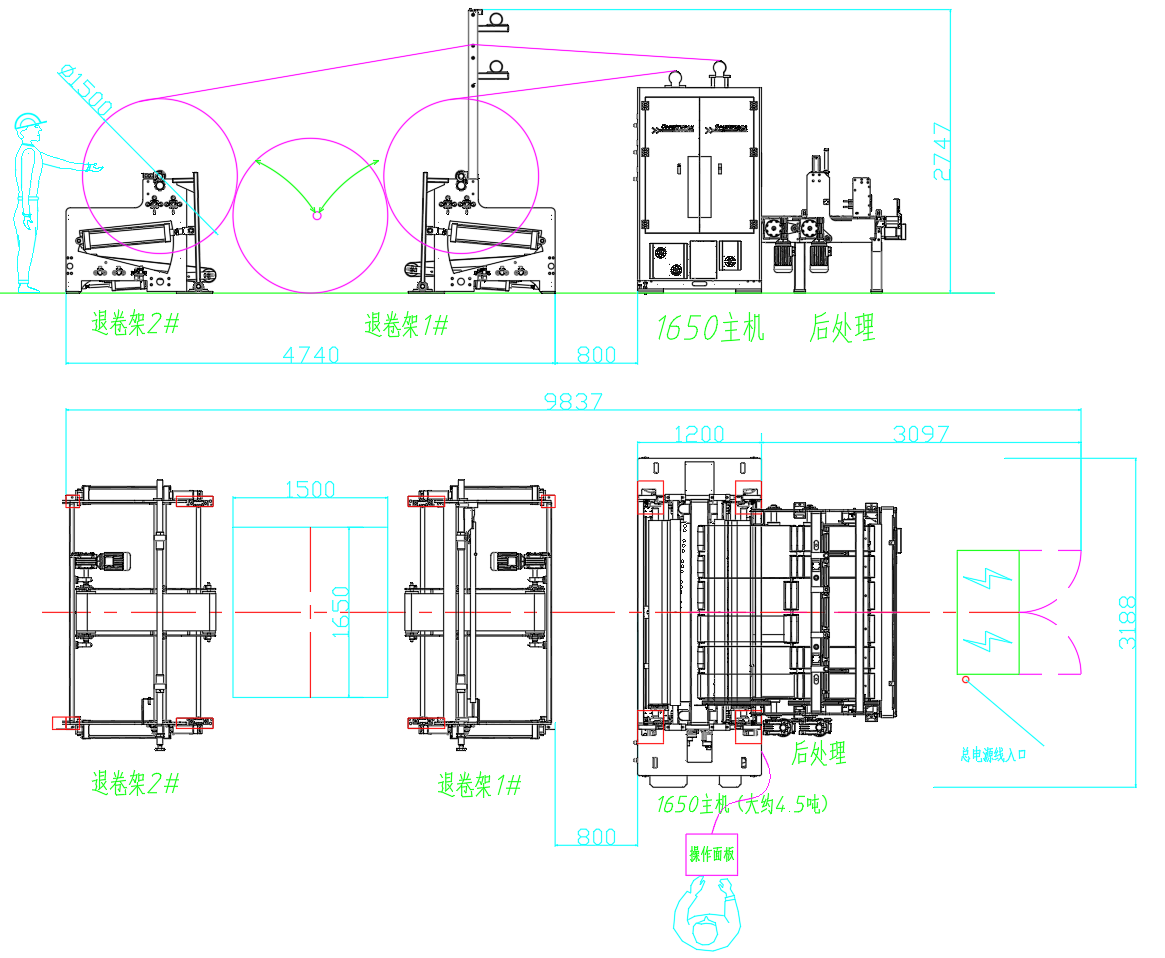

Overall dimension:(Basic configuration)

Technical parameters

SCZM-200-1650 Back stands

|

No. |

Item |

Technical data |

|

1 |

Max Jumbo roll width |

1650(mm) |

|

2 |

Diameter |

<=¢1500(mm) |

|

3 |

Release speed |

<120(m/min) |

|

4 |

Inner diameter |

¢76.3mm |

|

5 |

Machine structure |

Wall plate frame type |

|

6 |

Jumbo roll weight |

<0.4T |

|

7 |

Back stands system |

Single group belt |

|

8 |

Edge alignment |

By manual adjustment |

|

9 |

Original cloth fixed form |

Axial type |

|

10 |

Tension control |

Touch screen controls the adjusting tension |

|

11 |

Open roll type |

You can choose clockwise or counterclockwise winding |

|

12 |

Web cloth way |

Manual |

|

13 |

Broken cloth detection |

With the broken cloth detection system, the whole machine stops when the cloth breaks, to reduce the waste of the original cloth |

|

14 |

Power |

Main motor 1.5KW |

|

15 |

SCZP-1650 Deviation correcting device (optional) |

|

|

1、Correction accuracy+/—2mm; |

||

|

2、Linear velocity≤120 m / min |

||

|

3、Raw material alignment mode: one-sided + medium mode |

||

|

|

Drive |

|

|

16 |

Power |

Independent motor drive |

|

17 |

Send cloth belt |

Flat belt |

|

|

Other |

|

|

18 |

Guard |

The main transmission components are protected by shields |

|

19 |

Weight |

About 550KG |

SCZM-200-1650 Folding part:

|

No. |

Item |

Technical data |

|

1 |

Max Jumbo roll width |

1650 mm |

|

2 |

Design speed |

100 m/min |

|

3 |

Stable speed |

80 m/min or 5-8logs/min |

|

4 |

Broken cloth way |

Spirial blade fixed broken |

|

5 |

Machine structure |

Wall plate form |

|

6 |

Folding width |

200±2mm |

|

7 |

After folded size |

100(+1,+4)mm |

|

8 |

Bottom knife with lubricating oil |

Manual(Optional electric pump add oil) |

|

9 |

Folding type |

Vacuum adsorption, "V" type staggered folding |

|

10 |

Web cloth |

Manual |

|

11 |

S-shaped feeding device |

Using the S-shaped pull roller, you can adjust the tension through the touch screen |

|

12 |

Broken cloth detection |

It has the automatic stop function for cloth breaker detection |

|

13 |

Connecting cloth processing |

|

|

1、With sensor detection |

||

|

2、The screw cutter is separated to avoid the joint tape |

||

|

3、Spiral cutter closure |

||

|

4、Flip device and waste disposal or manual replacement. |

||

|

14 |

Vacuum power |

37KW_Vacuum pump |

|

15 |

Driving power |

5.5kw |

|

|

Drive |

|

|

16 |

Power |

Independent motor drive |

|

|

Other |

|

|

17 |

Guard |

The main transmission components are protected by shields |

|

18 |

Vacuum piping |

Vacuum tubes and construction are provided by the Buyer |

|

19 |

Weight |

About 3200KG |

SCDM-200-1650 Automatic stacking

|

No. |

Item |

Technical data |

|

1 |

Automatic stacking system |

Use servo motor independent control to achieve automatic folding function |

|

2 |

Main parts |

The aluminum alloy machined by CNC center ensures the precision of its folding |

|

3 |

Pneumatic component |

AirTAC pneumatic components |

|

4 |

Position tracking |

High precision servo encoder |

|

5 |

Sheets setting |

Set the number of stacks via the touch screen for 100% accurate counting (set base to an even number) |

|

6 |

Set range |

At least 100 pulls (depending on product height) |

|

7 |

Semi-finished product height range |

200-400mm (below 200mm need to be explained in advance) |

|

8 |

Fold times (Max.) |

8 logs |

|

9 |

Total power of servo motor |

9 KW |

|

10 |

Air pressure |

At least 0.6MPa |

|

11 |

WeightDynamic load factor |

About 1300KG |

|

12 |

Sheets setting |

1.2 |

SCZM-200-1650 Press cloth shaping system

|

No. |

Item |

Technical data |

|

1 |

Function |

This enables semi-finished products to better complete the final product and prepare for subsequent processes. |

|

2 |

Conveyor belt |

Use anti-static belts |

|

3 |

Drive way |

Independent frequency converter control |

|

4 |

Pressing method |

Adopt pneumatic pressurization form |

|

5 |

Photoelectric detection system |

The conveyor frame is equipped with photoelectric detection to ensure that there is no collision between semi-finished products. |

|

6 |

Height |

20-150mm |

|

7 |

Power |

0.75KW |

|

8 |

Weight |

About 320KG |

SCZM-200-1650 Pushing out system

|

No. |

Item |

Technical data |

|

1 |

Function |

This enables semi-finished products to better complete the final product and prepare for subsequent processes |

|

2 |

Conveyor belt |

Use anti-static belts |

|

3 |

Drive way |

Independent frequency converter control |

|

4 |

Pressing method |

Adopt cylinder + guide rail form |

|

5 |

Photoelectric detection system |

The conveyor frame is equipped with photoelectric detection to ensure that there is no collision between semi-finished products. |

|

7 |

Power |

0.75KW |

|

8 |

Weight |

Around 220KG |

Machine motor list and each part weight(For reference only)

|

Using position |

Power |

Qty |

Total |

||

|

1#Vacuum pump motor |

37KW |

1 |

37KW |

||

|

Back stands |

1.5KW |

2 |

3KW |

||

|

Folding machine main motor |

5.5KW |

1 |

5.5KW |

||

|

Front and back send cloth motor |

1.5KW |

2 |

3KW |

||

|

Jaw lifting servo motor |

2KW |

1 |

2KW |

||

|

Jaw moving servo motor |

1KW |

1 |

1KW |

||

|

Back claw lift servo motor |

2KW |

1 |

2KW |

||

|

Back claw moving servo motor |

1KW |

1 |

1KW |

||

|

Front split jaw lifting servo motor |

2KW |

1 |

2KW |

||

|

Front claw moving servo motor |

1KW |

1 |

1KW |

||

|

Post-processing conveyor belt motor |

0.25KW |

2 |

0.5KW |

||

|

Correction group motor (optional) |

0.55KW |

2 |

1.1KW |

||

|

Total: |

59.1KW |

||||

|

Name |

Weight(KG) |

Overall dimensions (Length, X, Width, X, Height, mm) |

Remarks |

||

|

Back stands |

540 |

2650X1450X2750 |

|

||

|

Deviation corrector |

700 |

2400X1825X1850 |

Optional |

||

|

Main machine |

4500 |

3200X1200X2300 |

|

||

|

Flip device |

820 |

2300X1400X1400 |

|

||

Capacity calculation:

Basic weight 60gsm, 1 layer, 2 groups of back stands, width 1650mm, efficiency coefficient 75%, production time 8h, production speed 100m / min, number of machines: 1; capacity:

100 (m / min) x1.65 (m) x60 (gsm) x1 (layer) x2 (group) x8 (hours) x60 (minutes) x1 (table) x0.75 (efficiency) 1000000=7.12 (tons)

|

Model |

Basic weight |

Working hours |

Production efficiency |

Pulls |

Speed (m / min) |

Logs |

Daily production |

|

200型 |

60g |

8 |

75% |

200 |

100 |

4 |

7.12Ton |

|

60g |

8 |

75% |

130 |

100 |

6.1 |

7.12Ton |

|

|

60g |

8 |

75% |

100 |

100 |

8 |

7.12Ton |

Quality guarantee and acceptance

The Seller guarantees that the folding machine can meet the following product quality acceptance standards:

Cross-cutting size: 200 ± 2mm, folding size: 100 (+ 1, + 4) mm;

Longitudinal size: ± 2mm (intermediate product);

100% accurate;

Fold neatly, no obvious defects such as folding or turning;

No appearance of the equipment factors caused by the product wrinkle, damage, oil pollution and other phenomena;

The bottom product speed acceptance is according to 1.4.6 capacity calculation table, 80 m / minute or 6 bars / minute, both take the first as the acceptance standard (80 m / minute is 60g pure cotton non-woven speed, the thickness of full adhesive or polyester content will affect the production speed);

The conventional product speed acceptance is 100 m / minute or 8 pieces / minute, and the acceptance standard is the first one (100 m / minute is 60g pure cotton non-woven cloth speed, and the thickness of the original cloth with full adhesive or polyester content will affect the production speed);

The incision end surface is flat, no incision knife black, hair edge, inclination error ± 2mm;

The equipment runs continuously for 4 hours, and the shutdown time caused by non-equipment reasons should be deducted, and the qualified rate of the product is 98% (excluding the roll joint, sampled samples and trimming waste)

Workshop environment:

Acceptance environment: the relative humidity during production is 45% rh-65% rh

Installation environment: please prepare the corresponding length and quantity of wires and pipelines before the equipment reaches the installation;

Power bus (35 square wire, 16 square ground and zero)

Fan power line (16 square four-core line)

PVC Air duct (φ200mm, pipe pressure resistance of 0.63MPa)

Air source equipment (air pressure 0.6MPa), gas pipe diameter 12mm

Vacuum requirement: -250- -350mmHg; flow rate: 42.56m3/min

Free spare parts list

|

No. |

Model |

Specification/Name |

Unit |

Quantity |

Renarks |

|

1 |

|

Breaking knife |

pcs |

1 |

|

|

2 |

|

Cutting knife |

pcs |

2 |

|

|

3 |

|

Buckle |

pcs |

6 |

|

|

4 |

|

High temperature tape |

roll |

1 |

|

|

5 |

|

Toolbox |

pcs |

1 |

|

|

6 |

|

Blower air gun |

pcs |

1 |

|

|

7 |

|

Vise |

pcs |

1 |

|

|

8 |

|

Scissors |

pcs |

1 |

|

|

9 |

|

Material belt |

pcs |

1 |

|

|

10 |

|

Wrench set |

set |

1 |

|

|

11 |

1.5-10 |

Allen wrench set |

set |

1 |

|

|

12 |

6x150 |

Slotted screwdriver |

pcs |

1 |

|

|

13 |

6x150 |

Phillips screwdriver |

pcs |

1 |

|

|

14 |

|

Shift fork |

pcs |

5 |

|

|

15 |

|

Stacking claw |

pcs |

5 |

|

|

16 |

LY2N-J DC24V |

Intermediate relay |

pcs |

1 |

|

|

17 |

E3FA-DN12 2M BY OMS |

Photoelectric switch |

pcs |

1 |

|

|

18 |

E2B-M12KN08-WZ-C1-2M |

Proximity switch |

pcs |

1 |

|

|

19 |

Z2BS54C |

Emergency stop button (Schneider) |

pcs |

1 |

|

|

20 |

ZB2BA5C |

Yellow jog button (Schneider) |

pcs |

1 |

|

|

21 |

ZB2BA3C |

Green jog button (NO) (Schneider) |

pcs |

1 |

|

|

22 |

ZB2BD2C |

Second gear knob (normally open) (Schneider) |

pcs |

1 |

|

|

23 |

LRN 07N(1.6-2.5A) |

Thermal relay (CHINT) |

pcs |

1 |

|

|

24 |

NXB 1P D4A |

Circuit breaker (CHINT) |

pcs |

1 |