SP-S-220 Handketchief Pocket Tissue High Speed Folding Machine

|

Handkerchief Pocket Tissue Production Line |

|

| Equipment Name | Handkerchief Pocket Tissue Full Automatic Folding and Packaging Production Line |

| Equipment Model | -220A |

| Parent Roll Stands | Two |

| Parent Roll Width | 420mm ± 3mm |

| Parent Roll Diameter | ≤Φ1500mm |

| Core Diameter | Φ76 mm |

| Applicable Parent Roll | 13-16g/m² three-layer paper; 12-15g/m² four-layer paper |

| Finished Product Size | 210mm ± 2mm × 210mm ± 2mm |

| Finished Product Specifications | 72(105) ± 2mm × 53 ± 2mm × 24mm ± 2mm |

| Rated Total Power | 33.5KW for the production line (including a 18.5KW vacuum pump) |

| Power | 380V, 50 Hz |

| Paper Guide System | Correction System, Infrared automatic correction |

| Embossing Equipment | 1 set |

| Calendering Equipment | 1 set |

| Recycling System | Vacuum pump connected to recycling bin |

| Packaging Count | 6-10 sheets per pack (adjustable with molds) |

| Film Positioning | Electric control |

| Film Diameter | ≤Φ350mm, Core Inner Diameter φ76mm, Width ≤145mm, Material PE film, Thickness 0.040-0.05mm |

| Film Label Interval | 146mm-152mm |

| Paper Feeder | 10 sets, connecting rod type |

| Packaging Form | 12 units (Flower-shaped disc) |

| Film Sealing | Heat-sealing with a heating wire 220V, 1000W |

| Design Speed | 220 packs (10 sheets)/min |

| Operation Speed | 180 packs (10 sheets)/min |

| Equipment Dimensions | Length 16m, Width 4.6m, Height 2.2m (including middle packaging machine) |

| Label | Width 30mm, Diameter 300mm, Inner Diameter 75mm |

| Equipment Supply Scope | Folding Unit: 1, Small Pack Unit: 1, Labeling Machine: 1, Embossing System Unit: 1 (customized), Vacuum Pump Negative Pressure Unit: 1, Middle Packaging Machine: 1, Waste Collection Unit: 1 |

| Middle Packaging Machine Parameters | |

| Total Power | 4.8KW |

| Input Voltage | 380V 50Hz |

| Dimensions | 2400mm x 1600mm x 1400mm (main unit) |

| Weight | 1000KG |

| Packaging Speed | Guaranteed value of 16 packs/min |

| Acceptance Rate | Above 98% |

| Effective Operation Rate | Above 95% |

| Small Pack Specifications | Super mini pack size: 62mm x 48mm x 19mm |

| Conveyor Line | 2.2 meters |

| Main Packaging Specifications | 3×2×1 (Columns × Layers × Rows), 3×3×1, 4×2×1; other specifications can be customized |

| Compressed Air | 0.6Mpa |

Main Components Configuration Table

(1) Handkerchief Paper Full Automatic Production Line Configuration Table

| No. | Name | Brand/Manufacturer |

|---|---|---|

| 1 | Programmable Logic Controller (PLC) | Germany Siemens |

| 2 | Touch Screen Panel Component | Germany Siemens |

| 3 | Variable Frequency Drive | Germany Siemens |

| 4 | Infrared Photoelectric Detection Sensor System Component | SICK |

| 5 | Label Detector | SICK |

| 6 | Position Sensing System Component | BST |

| 7 | Power Switch/Circuit Breaker | France Schneider |

| 8 | Correction Device | Beiren |

| 9 | Intelligent Temperature Control Module Component | France Schneider |

| 10 | DC Stabilized Power Supply | France Schneider |

| 11 | Solid State Relay | Meager |

| 12 | Main Power Switch | France Schneider |

| 13 | Start Switch | France Schneider |

| 14 | Jog Switch | France Schneider |

| 15 | Emergency Stop Switch | France Schneider |

| 16 | Run Switch | France Schneider |

| 17 | Terminal Block | Shanghai Relp |

| 18 | Switching Power Supply | France Schneider |

| 19 | Medium Voltage Circuit Breaker | France Schneider |

| 20 | Variable Speed Motor | Jiangsheng |

| 21 | Pneumatic Components | Yadeke |

| 22 | Vacuum Pump | Shige |

| 23 | High Pressure Blower | Shige |

| 24 | Main Position Non-seat Bearings | Japan NSK |

| 25 | Seat Bearings | LK |

| 26 | Linear Guide Rail | Yadeke |

(2) Mid-sized Packaging Machine Configuration Table

| No. | Name | Origin |

|---|---|---|

| 1 | Rodless Cylinder | Yadeke |

| 2 | Linear Cylinder | Yadeke |

| 3 | Solenoid Valve | Yadeke |

| 4 | Air Source Triple Connector | Yadeke |

| 5 | Servo Motor | Siemens |

| 6 | Reducer Motor | Zhujiang |

| 7 | Bearing | HRB |

| 8 | Linear Guide Rail | Yadeke |

| 9 | Variable Frequency Drive | Siemens |

| 10 | PLC | Siemens |

| 11 | Human-Machine Interface | Siemens |

| 12 | Proximity Switch | SICK |

| 13 | Photoelectric Switch | Beifuning |

| 14 | Color Mark Sensor | SICK |

| 15 | Temperature Control Meter | Beiqi |

| 16 | Coding Machine | Zhangzhou Nanyun |

Specialized Tools List

| No. | Name | Specification | Quantity | Unit |

|---|---|---|---|---|

| 1 | Double-ended Stubby Wrench (Imported) | 5.5×7 | 1 | piece |

| 2 | Double-ended Stubby Wrench (Imported) | 8×9 | 1 | piece |

| 3 | Double-ended Stubby Wrench (Imported) | 10×12 | 1 | piece |

| 4 | Double-ended Stubby Wrench (Imported) | 14×17 | 1 | piece |

| 5 | Double-ended Stubby Wrench (Imported) | 17×19 | 1 | piece |

| 6 | Double-ended Stubby Wrench (Imported) | 22×24 | 1 | piece |

| 7 | ||||

| 8 | Imported Ball-End Allen Wrench | 1.5~12 | 1 | piece |

| 9 | Imported Flat Head Screwdriver | 3×75 | 1 | piece |

| 10 | Imported Cross Head Screwdriver | 3×75 | 1 | piece |

| 11 | Imported Flat Head Screwdriver | 5×100 | 1 | piece |

| 12 | Imported Cross Head Screwdriver | 5×100 | 1 | piece |

| 13 | Imported Steel Wire Pliers | 175 | 1 | piece |

| 14 | Needle-nose Pliers | 150±8 | 1 | piece |

| 15 | Imported Circlip Pliers | 10~50 | 1 | piece |

| 16 | Imported Nylon Hammer | 35 | 1 | piece |

| 17 | Iron Maul | 0.44 | 1 | piece |

| 18 | Gauge Block | 150×77 | 1 | piece |

| 19 | Steel Ruler | 1 | piece | |

| 20 | Steel Tape Measure | 1 | piece | |

| 21 | Tweezers | 1 | piece | |

| 22 | Hook Wrench | 41~46 | 1 | piece |

| 23 | Tool Box | 1 | piece |

Random Vulnerable Parts List

| No. | Part Number/Model | Name | Note |

|---|---|---|---|

| 1 | 140×30×8 | N-type folding roller cutting knife | For small packaging machine |

| 2 | 130×46×3 | High-speed steel blade | For small packaging machine |

| 3 | 179×61×3.5 | Film cutting bottom knife | For small packaging machine |

| 4 | 180×24×12 | Film cutting upper knife | For small packaging machine |

| 5 | 115×14×3.5 | N-type one-fold folding knife | For small packaging machine |

| 6 | 115×20×3.5 | N-type two-fold folding knife | For small packaging machine |

| 7 | 145×135/1300W | Embedded heating wire electric heating plate | For small packaging machine |

| 8 | 220V1000W 340×16(MM) | Heating rod | For small packaging machine |

| 9 | K-type 5M φ4(Round head) | Thermocouple | For small packaging machine |

| 10 | K-type 3M M6(Thread) | Thermocouple | For small packaging machine |

| 11 | 6×30 1A | Glass fuse | For small packaging machine |

| 12 | 1350×150×0.16 | High-temperature belt | For small packaging machine |

| 13 | 2300×30×0.16 | High-temperature belt | For small packaging machine |

| 14 | 680H-34.6 | Belt with hole synchronous belt | For small packaging machine |

| 15 | d5 | Transparent PU round belt | For small packaging machine |

| 16 | d1.5 | Fishing line | For small packaging machine |

| 17 | D10.5×d1.5×120 | Tension spring | For small packaging machine |

| 18 | Paper pushing rod | For small packaging machine | |

| 19 | Top package rod | For small packaging machine | |

| 20 | LMF13 | Linear bearing | For small packaging machine |

| 21 | LM13 | Linear bearing | For small packaging machine |

| 22 | 470×23.5×7 | Fixed film cutting knife | For medium packaging machine |

| 23 | 460×28×10 | Moving film cutting knife | For medium packaging machine |

| 24 | K-type 3M φ4(Round head) | Thermocouple | For medium packaging machine |

| 25 | 1000W220V 380×10(MM) | Heating tube | For medium packaging machine |

| 26 | 1000W220V 400×12(MM) | Heating tube | For medium packaging machine |

| 27 | RT18-3A | Fuse | For medium packaging machine |

| 28 | 1235×100 | High-temperature belt | For medium packaging machine |

| 29 | D8×d1.1×35.8 | Tension spring | For medium packaging machine |

| 30 | Movable edge folding fixed block | For medium packaging machine |

(2) Vulnerable Parts List

| No. | Part Number/Model | Name | Note |

|---|---|---|---|

| 1 | 140×30×8 | N-type folding roller cutting knife | For small packaging machine |

| 2 | 130×46×3 | High-speed steel blade | For small packaging machine |

| 3 | 179×61×3.5 | Film cutting bottom knife | For small packaging machine |

| 4 | 180×24×12 | Film cutting upper knife | For small packaging machine |

| 5 | 115×14×3.5 | N-type one-fold folding knife | For small packaging machine |

| 6 | 115×20×3.5 | N-type two-fold folding knife | For small packaging machine |

| 7 | 145×135/1300W | Embedded heating wire electric heating plate | For small packaging machine |

| 8 | 220V1000W 340×16(MM) | Heating rod | For small packaging machine |

| 9 | K-type 5M φ4(Round head) | Thermocouple | For small packaging machine |

| 10 | K-type 3M M6(Thread) | Thermocouple | For small packaging machine |

| 11 | 6×30 1A | Glass fuse | For small packaging machine |

| 12 | 1350×150×0.16 | High-temperature belt | For small packaging machine |

| 13 | 2300×30×0.16 | High-temperature belt | For small packaging machine |

| 14 | 680H-34.6 | Belt with hole synchronous belt | For small packaging machine |

| 15 | d5 | Transparent PU round belt | For small packaging machine |

| 16 | d1.5 | Fishing line | For small packaging machine |

| 17 | D10.5×d1.5×120 | Tension spring | For small packaging machine |

| 18 | Paper pushing rod | For small packaging machine | |

| 19 | Top package rod | For small packaging machine | |

| 20 | LMF13 | Linear bearing | For small packaging machine |

| 21 | LM13 | Linear bearing | For small packaging machine |

| 22 | 470×23.5×7 | Fixed film cutting knife | For medium packaging machine |

| 23 | 460×28×10 | Moving film cutting knife | For medium packaging machine |

| 24 | K-type 3M φ4(Round head) | Thermocouple | For medium packaging machine |

| 25 | 1000W220V 380×10(MM) | Heating tube | For medium packaging machine |

| 26 | 1000W220V 400×12(MM) | Heating tube | For medium packaging machine |

| 27 | RT18-3A | Fuse | For medium packaging machine |

| 28 | 1235×100 | High-temperature belt | For medium packaging machine |

| 29 | D8×d1.1×35.8 | Tension spring | For medium packaging machine |

| 30 | Movable edge folding fixed block | For medium packaging machine |

Random Equipment Information

| No. | Name | Quantity | Unit |

|---|---|---|---|

| 1 | Packaging List for Handkerchief Production Line | 2 | copies |

| 2 | User Manual for Handkerchief Production Line | 2 | copies |

| 3 | User Manual for Handkerchief Middle Packaging Machine | 2 | copies |

| 4 | Electrical Schematic Diagram for Handkerchief Production Line | 2 | copies |

| 5 | Electrical Schematic Diagram for Handkerchief Middle Packaging Machine | 2 | copies |

| 6 | Random Spare Parts Catalog | 2 | copies |

| 7 | Vulnerable Parts Catalog | 2 | copies |

The above mentioned random accessories, special tools, and random information will be provided by the seller free of charge and delivered to the user along with the equipment. Any additional spare parts requirements beyond the scope will be resolved through separate negotiations between both parties. (The aforementioned vulnerable parts may vary with each equipment update)

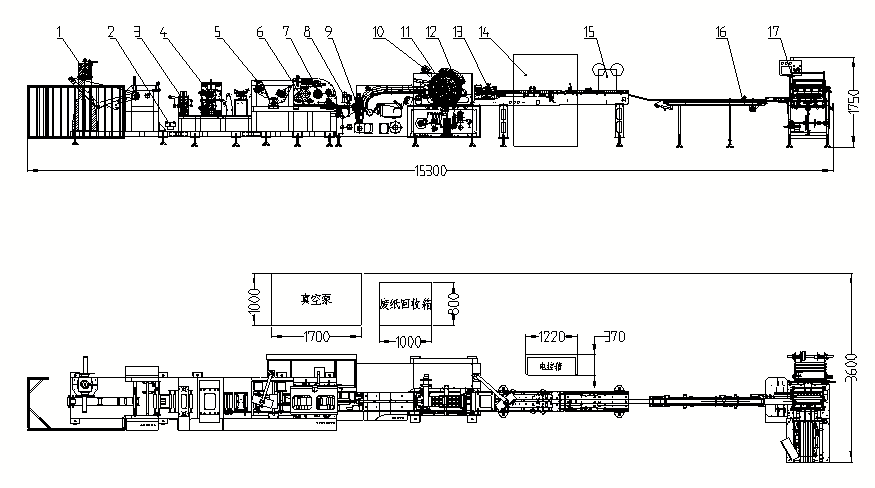

Layout Plan of Equipment and Structure Diagram of Equipment

1.Original paper rewind section

2.Automatic alignment system

3.Calendering section

4.Embossing section

5.Longitudinal folding section

6.Cross-cutting device

7.Cross-folding section

8.Waste paper collection device

9.Paper stacking section

10.Waste film collection device

11.Side forming and sealing device

12.Packaging wheel section

13.End sealing section

14.Electrical control box

15.Labeling machine

16.Conveying section

17.Middle packaging machine section